10/13/2020

Increase the productivity of your Coil machines!

The reinforcement processing industry focuses too often the attention only on two factors: how fast a machine is and up to which diameter it works.

These two aspects are important but alone they are not enough; there are many other undervalued factors, which are essential to improve and increase the production of your coil machine.

Even if your stirrup bender machine from coil is fast and very performing, it will be useless if it stands still for half the time it could work!

Usually, a bar shaping machine from coil works 35 minutes/hour and the remaining 25 minutes (machine downtime) are used to change the diameter, to load or change the coil, to unload the processed product from the carriage, to handle the finished product ...

To significantly reduce the downtime of your coil machine, Schnell offers you innovative and advantageous solutions, guaranteeing production continuity with a consequent production increase.

Among Schnell innovations to improve the logistics and productivity of your production plant there are:

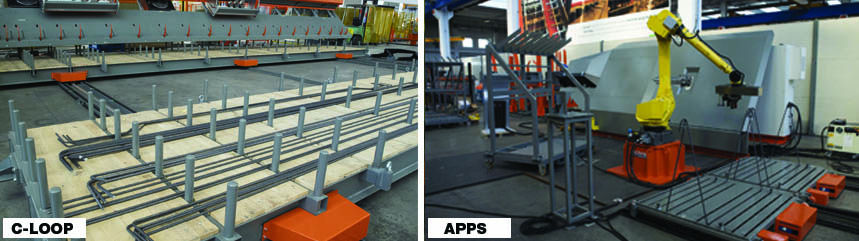

- C-Loop unloading system (Patented): the innovative automatic system consisting of two unloading carriages for the collection of shapes that move on rails: production continuity guarantees an increase in productivity of up to 20%. Go to the article.

- stirrups unloading system through APPS and unloading carriages. It allows the production of stirrups without ever stopping: this solution guarantees production continuity with a consequent increase in productivity up to 20-30% more than the manual use of the stirrup bender. Go to the article.

- loading and unloading of coils in hidden time.