6/18/2021

Schnell & Presider: a challenge met successfully!

Presider Spa is a leading company in cutting and shaping wire processing on the European territory; part of the Feralpi group, it mainly meets the requests of big construction companies that build great infrastructures.

The need to renovate the Borgaro Torinese plant, the optimization of the logistics and production processes of the shaping center led Presider to involve Schnell in this new challenge.

Challenge welcomed with enthusiasm by the Schnell team who immediately set to work to study and define an effective and efficient action plan!

“Our goal was to study a new layout and to improve the production efficiency while keeping the procedures in place – says Dr. Simone Rupoli, Schnell Spa CEO. “It was important to find the right balance between the desire for new and the productive reality of the wire processing plant”.

Together with Presider technicians, Schnell experts have set the goals to achieve, analyzing the production needs and then undertaking a restructuring of the plant.

"The difficulty of this ambitious project was to implement new investments without interrupting the production!" underlines Fabio Baldoni, Schnell Spa Technical Manager.

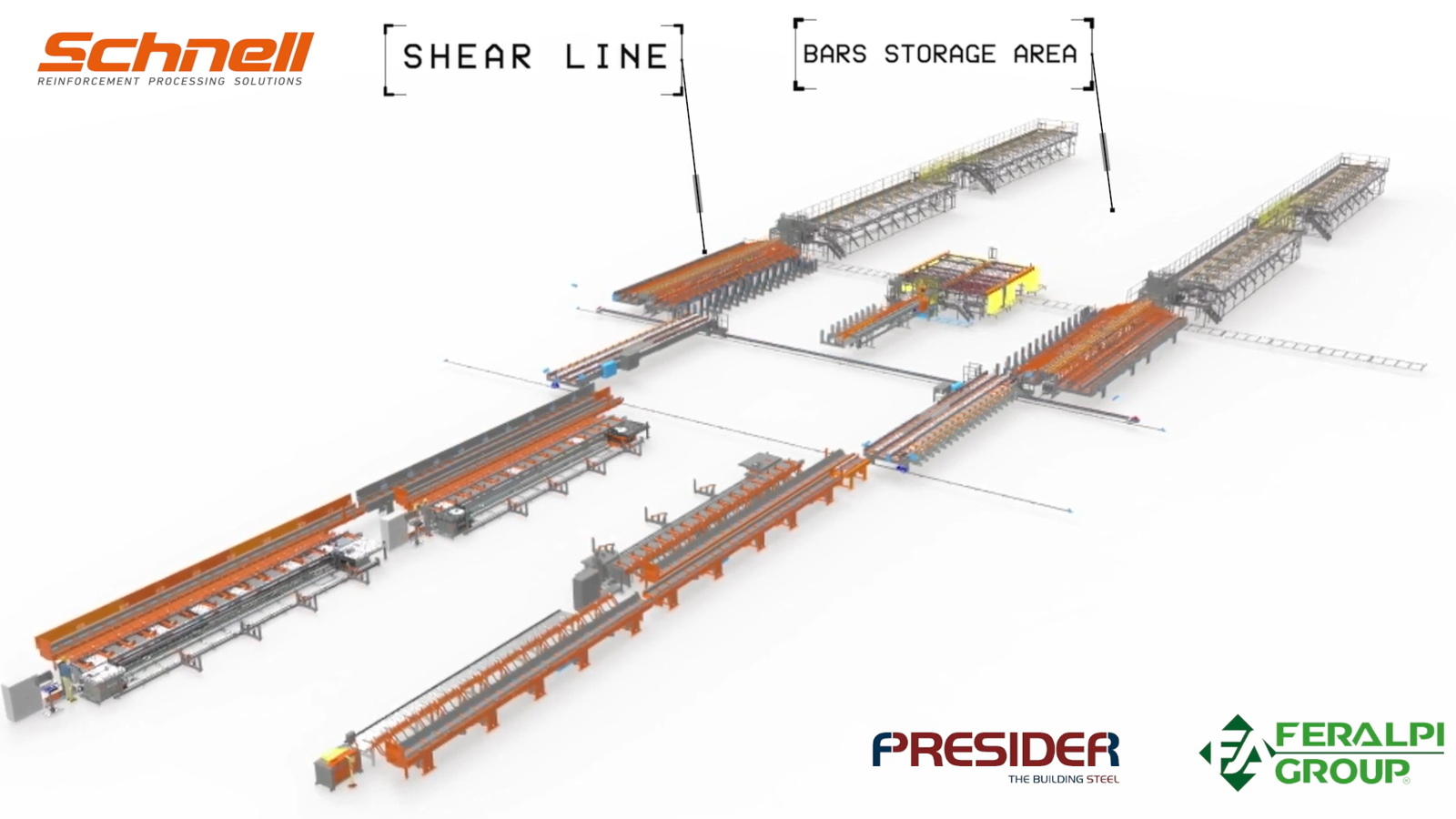

In detail, Schnell solution intervened at 360° in the Borgaro Torinese plant,

- By reorganizing the raw materials warehouse;

- Redesigning the lay-out of the cutting lines;

- Including an important material storage area on the ground;

- Innovating the bending machines placed at the end of the cutting lines.

"The implementation of the new machines and the new layout in Presider has allowed us to have an important logistics optimization of the raw material and consequent production gain." tells us Mr. Piero Vanzino, Presider Production Project Manager - "The cutting lines installed in 2020 allow operators safety, precision and comfortable operation processes".

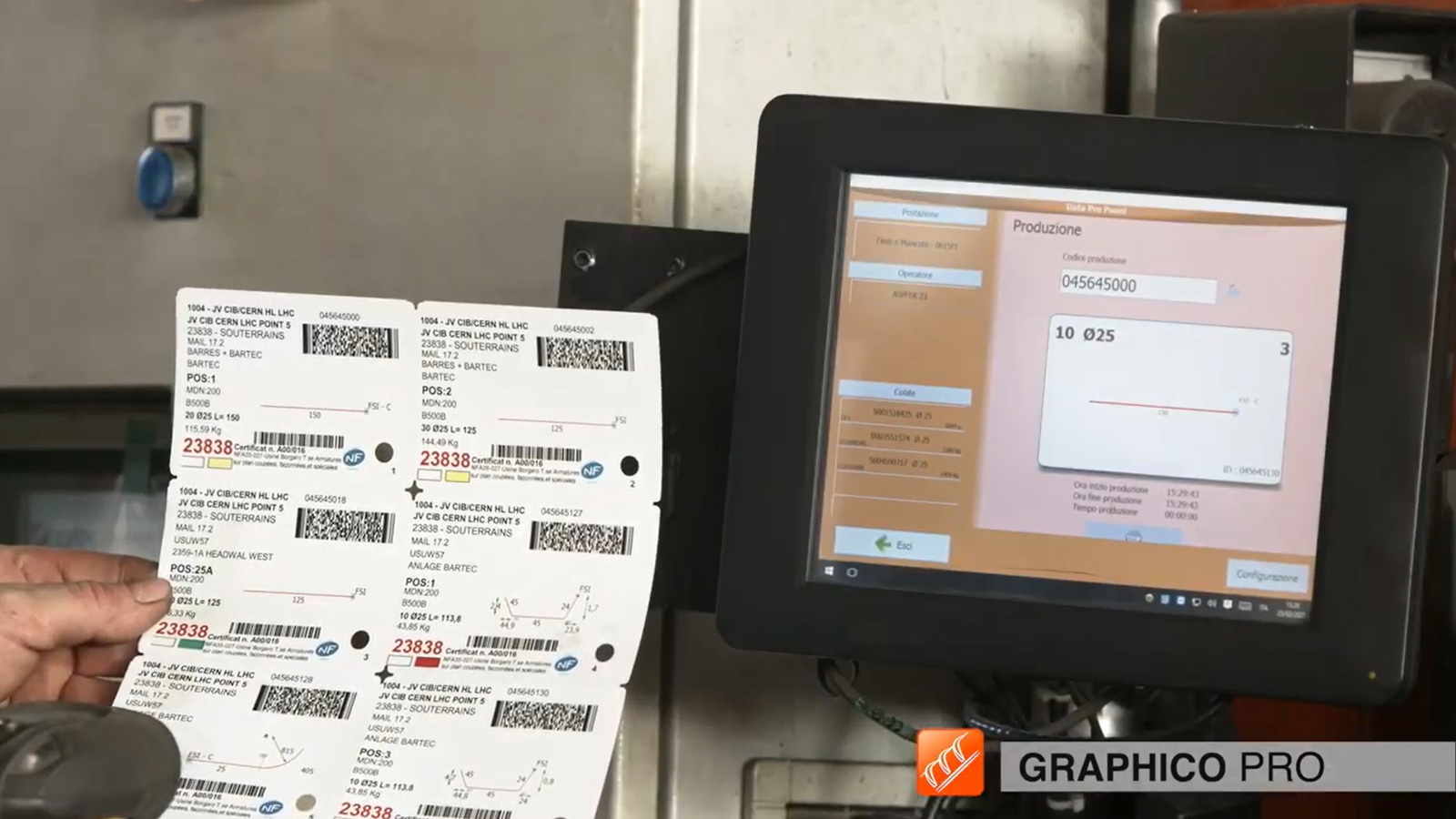

We have studied a practical solution for the recycling of scraps inside the plant, based on the Shear Line 150 cutting system, specially modified in the mechanics and supported by the Graphico software, designed to fully integrate this cutting line within the flow of production data.

“Next to the main plant dedicated to the processing of large orders - explains Marco Cesari, Mechanical Design Manager of Schnell Spa - we have added an area dedicated to residential building processing equipped with stirrup benders and shaping machines, from bar and coil”.

In particular, the automatic stirrup bender-shaping machine Bar Wiser 28 also performs the function of cleaning the cutting lists.

The Borgaro Torinese plant is managed and organized by Graphico, Schnell Software's technical software for the management of the wire processing center in its productive phases: bars differentiation, production optimization, assignment of labels to the machines, orders traceability, shipping. In addition to supervising all production data, Graphico is connected with the SAP management system of Feralpi Group and incorporates all the typical parameters of industry 4.0.

"All the machines are connected to the Graphico software for traceability, warehouse management and scraps recovery integration," explains Francisco Tolosa, Schnell Spa Software Manager, "allowing the optimization of the production process which leads to a costs reduction and increased efficiency of the wire processing center ".

The renovation of Presider's production plant and the new logistics and production solution implemented by Schnell generated great satisfaction, as underlines Mr. Elia Zuin, Presider's Technical Manager:

“Graphico has brought Presider to a very high level of digitization; the implementation of Graphico was a great challenge which turned out to be a great success and we are very satisfied with it.

The software has been installed on all our factories and allows us to have control both at the production and management level of all the activities and the monitoring of the machines and their performance.”

An important challenge for Schnell successfully won, as confirmed by Simone Rupoli: