7/15/2021

Colli al Metauro

Schnell changes the world of Industrial Wire Straightening!

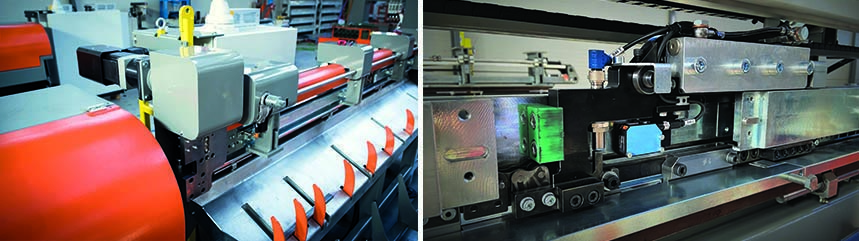

Schnell’s industrial wire straightening machines with integrated Automatic-Length Changer (PATENT) and innovative Column Cutting Unit are changing wire straightening manufacturing concepts.

The "RI" rotor wire straightening machines guarantee cost-cutting and just-in-time processing: wire straightening has never been easier.

The automatic-length changer enables the operator to log into the machine’s PC a number of different bar lengths, cutting them all in quick succession without ever having to stop the machine. The system guarantees bar length accuracy of +/-0.1mm.

The column cutting unit, quite different to the conventional pivot cut, has been relocated on the measuring bench allowing the machine to gain greater stability as well as ensuring that the new column cut produce bars with a perfectly burr-free 90° end-finish cut.

The servo-motor bar bench release (replacing pneumatics) guarantees perfect synchronization between the cut and bar release.

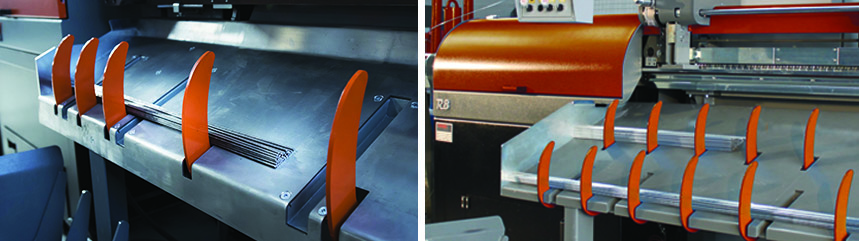

The bench is available with a single or double stocking magazine to enable the machine to process and sort different bar lengths without the need to supervise or remove the bars from the magazine immediately.

The Schnell “RI” series of straighteners are compact, user friendly and environmentally safe.

Schnell's “RI” straightening machines are the perfect solution to process a wide range of steel wires for a diverse number of industrial applications:

- fencing-gabions

- white products

- shop fittings

- furniture

- automotive

- agriculture

- many other...