1/29/2024

Flexiweld: automatic and flexible production of special mesh for the precast industry!

Electro-welded mesh is essential in the precast industry for the construction of residential, commercial and industrial structures.

They are a versatile and effective solution for reinforcing concrete used in the construction of pillars, beams, walls and other precast elements.

The use of electro-welded mesh in prefabrication offers many advantages

- greater structural strength;

- faster installation;

- design flexibility;

- cost savings.

Electro-welded mesh used in precasting must meet specific standards and requirements to ensure the safety, structural stability and durability of precast constructions; it must also comply with industry regulations and standards.

To meet the needs of customers and markets around the world, AWM created Flexiweld in 1993, the first machine for just-in-time production of electro-welded mesh for precasting.

The Flexiweld flexible plant provides many key benefits:

• High efficiency: thanks to full automation, production processes become significantly faster;

• Space-saving in the factory, providing a compact and efficient solution;

• High Quality: the continuous and precise bar cutting ensures superior quality of the final product.

• Increased Flexibility and Versatility: fast diameter changes increase the flexibility and versatility of the production process.

• Reduced Downtime: thanks to its advanced technology, Flexiweld minimises downtime during coil changes, ensuring continuous production.

Flexiweld continues to evolve over the years and today produces custom-made welded mesh for prefabricated elements such as walls, floors and mesh with door and window openings.

Each mesh is manufactured with precision to ensure a perfect fit to customer requirements.

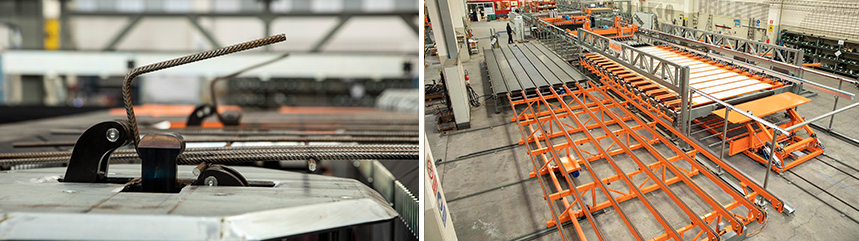

The plant integrates and automates the different stages of the production process, equipping itself with systems for the automatic handling and positioning of reinforcements, automatic bending machines and the Mirrorweld system for welding top and bottom.

Flexiweld is, therefore, the ideal machine for precasters and manufacturers of both standard and special mesh, which is why it is now being used in plants all over the world!

With the technical expertise gained from over 30 years of experience and the global service that Schnell has always guaranteed, AWM now offers its customers reliable and prompt after-sales service!

AWM assists its customers at 360°, from consulting during the study and design phase to technical support after the delivery and installation of the machine, guaranteeing the best solutions in terms of investment, logistics and production requirements.

A story of success, innovation and reliability that has been going on for 30 years!