Automatic rotor straightening machine suitable for processing all types of industrial wire from Ø 6 to Ø 13 mm.

Automatic rotor straightening machine suitable for processing all types of industrial wire from Ø 6 to Ø 13 mm.

The best straightening system

The rotor with its independently controlled servomotor has a wide spinning range which allows processing diverse typologies of industrial wire.

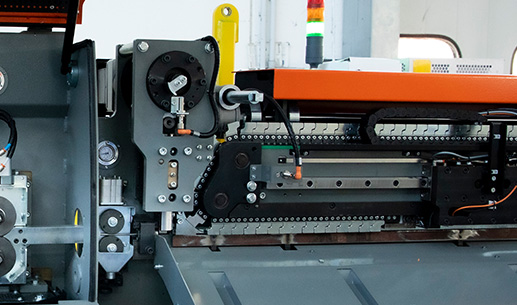

Advanced cutting unit

The newly designed column shear positioned on the measuring bench allows the machine to gain greater stability and obtain precision cuts at 90° and burr-free.

Innovative automatic bar length setting system

Production under control

The machine’s PC with 8” touchscreen allows accurate settings of all the principal servo-driven functions.

Principal features:

- Loading of any new production batch without having to interrupt the machine’s current production cycle;

- Active “Diagnostics System’’ ensuring the machine is under constant monitoring of all its functions.

- Consultation, storing, saving and filing all production data of the machine subdivided into categories: days/shift and wire diameters.

- It is possible to insert data manually using pen-drive USB, reading off Bar Codes or downloading data from a remote PC.

Suitable for every production need

The wide range of equipment, accessories (straightening dies, feed rolls, cutting bushes and knives) and optional meet all the processing requirements and allows the processing of multiple materials.

Technical data

RI 6

wire straightening machine- 2,5-6 mm

Wire diam. 400-800 N/mm2 - 2,5-5 mm

Wire diam. 800-1200 N/mm2 - 2,5-4 mm

Wire diam. 1200-1600 N/mm2 - 160 m/min

Max. Pulling Speed - 180

N° Cuts/min - 360

N° Cuts/min in "continuous mode" - ±0.1 - ±0.2 mm

Length tolerance depending on the diameter -

VERSIONE EVO:

- Pulling Unit

1 Servomotor - Bar length stop

Manual

VERSIONE PREMIUM:

- Pulling Unit

2 servomotors - Bar length stop

Automatic

RI 8

wire straightening machine- 3-8 mm

Wire diam. 400-800 N/mm2 - 3-6 mm

Wire diam. 800-1200 N/mm2 - 3-4 mm

Wire diam. 1200-1600 N/mm2 - 160 m/min

Max. Pulling Speed - 180

N° Cuts/min - 360

N° Cuts/min in "continuous mode" - ±0.1 - ±0.2 mm

Length tolerance depending on the diameter -

VERSIONE EVO:

- Pulling Unit

1 Servomotor - Bar length stop

Manual

VERSIONE PREMIUM:

- Pulling Unit

2 servomotors - Bar length stop

Automatic

RI 10

wire straightening machine- 4-10 mm

Wire diam. 400-800 N/mm2 - 4-8 mm

Wire diam. 800-1200 N/mm2 - 4-6 mm

Wire diam. 1200-1600 N/mm2 - 160 m/min

Max. Pulling Speed - 140

N° Cuts/min - 240

N° Cuts/min in "continuous mode" - ±0.1 - ±0.2 mm

Length tolerance depending on the diameter -

VERSIONE EVO:

- Pulling Unit

1 Servomotor - Bar length stop

Manual

VERSIONE PREMIUM:

- Pulling Unit

2 servomotors - Bar length stop

Automatic

RI 13

wire straightening machine- 6-13 mm

Wire diam. 400-800 N/mm2 - 6-10 mm

Wire diam. 800-1200 N/mm2 - 6-8 mm

Wire diam. 1200-1600 N/mm2 - 160 m/min

Max. Pulling Speed - 140

N° Cuts/min - 240

N° Cuts/min in "continuous mode" - ±0.1 - ±0.2 mm

Length tolerance depending on the diameter -

VERSIONE EVO:

- Pulling Unit

1 Servomotor - Bar length stop

Manual

VERSIONE PREMIUM:

- Pulling Unit

2 servomotors - Bar length stop

Automatic